"Multiplicity ought not to be posited without necessity."

— Occam's Razor

William of Ockham (1285-1349)

Otherwise stated:

Everything should be as simple as possible,

but not simpler.

|

Split Flow Process Pumps Save Energy

Application for DOE Nice3 Program

I. Project and applicant information

- Project Title: Split Flow

Purpose: The Split Flow feature for API (American Petroleum Institute) Standard centrifugal process pumps allows use of smaller motors and saves operating kW for dual service applications.

- Contact: William E. Murray and Bruce T. Murray.

- Address, telephone number, and e-mail: See contact information at the bottom of this Web page.

- Other cost-sharing partners: Martinez Refining Co., Martinez, Calif.

Equipment supplier: Power Machinery, Inc., Houston, Texas.

- Sponsoring State Agency: Texas Industries of the Future.

- Is there at least 50 percent of non-federal cost share for the total project cost? Yes.

- Targeted OIT focus industries: Petroleum refining and petrochemical.

II. Technology Discussion

- Conventional Technology: Standard process designs for petroleum refinery and petrochemical plant pump installations provide for two, 100 percent capacity pumps for each process service — one operating and one standby. Common practice for electric motor-driven centrifugal pump applications in dual service is to use either:

(a) Two pairs of pumps, each pair sized and selected for a discrete-particular flowstream. This requires extra capital for initial installation and lifecycle maintenance for four pumps instead of two; or,

(b) Two pumps oversized to envelop both flowstreams. This requires larger pumps and motors and wastes energy.

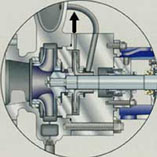

- Proposed technology and its innovative aspects: The patented Split Flow feature modifies API Standard pump designs to provide the service requirements for two separate flowstreams.

- Why the proposed technology is an improvement over conventional technology: Conventional pump designs and installations heretofore did not address dual service applications and typically use oversized pumps and motors with resultant waste of kW (electric energy).

Use of the Split Flow feature provides unique benefits, including:

(a) Permits use of two pumps instead of four, resulting in capital savings;

(b) Allows use of smaller motors, resulting in kW savings;

(c) Provides better pump-to-system hydraulic fit, as defined by API criteria;

(d) Results in longer MTBR (mean time between repairs) for seals and bearings.

III. Commercial Potential

- R&D activities and experience to date: Two prototype 60 hp Split Flow-modified pumps were installed fractionator reflux services at the Shell Martinez refinery in June, 1996. This prototype pump design used a drilled-hold type auxiliary impeller and external feed from the primary pump discharge to the auxiliary impeller suction. Conventional pumps for this service would have used 125 hp motors. This installation has proven the viability of the Split Flow concept.

The proposed project for commercial demonstration pumps would use an improved design. This improved design would embody a radial type auxiliary impeller and internal feed from the primary impeller discharge to the auxiliary impeller suction.

- Potential markets for the proposed Split Flow technology: there are 180 petroleum refineries in the United States, ranging in size from approximately 5,000 to 340,000 bbl per day. Of these refineries, 20 may have applications for dual services where Split Flow-fitted pumps could be used.

All petroleum refineries use fractional distillation towers. Most towers have applications for Split Flow (dual service) pumps. Of the 40 towers used in an average 94,000 bbl per day refinery, 20 may have applications for dual services were Split Flow-fitted pumps could be used.

Refinery processes and equipment are sometimes modified and upgraded to increase thru-put and efficiency and also address environmental issues. It is feasible to rework existing pumps to incorporate the Split Flow feature and reduce operating kW.

Petrochemical plants also have towers, some of which could use Split Flow pumps for dual-service applications.

IV. Energy, environmental and economic savings:

The prototype Split Flow pump installation saves approximately 50 kW or 438,000 kWh per year. At the refinery rate of $0.06 / kWh, use of the smaller motors results in an annual savings of $26,000. This installation also saved approximately $240,000 in installed equipment costs by using two Split Flow-fitted pumps instead of four conventional pumps.

Maintenance costs are approximately 50 percent for two pumps compared with four pumps.

|

Split Flow™

Application for U.S. Department of Energy National Industrial Competitiveness Through Energy, Environment, and Economics (Nice 3) Program

Outline

|