"Multiplicity ought not to be posited without necessity." — Occam's Razor |

‘Big’ Split Flow™ is hereThe United States Patent Office has issued the patent for the 2015 edition of Split Flow — an innovative API centrifugal pump that employs two different impellers in the same pump casing. The new Split Flow applies to both overhung and between bearing pumps. The new patent is a substantial upgrade from the original, 1997 version of Split Flow, which only covered overhung pumps. Read more about the new Split Flow™ here, and a succinct summary here. Why Split Flow?

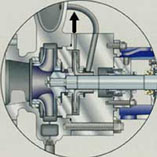

Split Flow in action:Two Split Flow prototype pumps were installed in June, 1996 at the Shell refinery in Martinez, Calif., and operated successfully throughout the duration of the pumps' service lifetime. Read more about the Shell project here.

In a nutshell:Split Flow technology can be applied to save significant capital and operating costs for API pump installations. This savings is enjoyed by the refiner, the customer and the environment. Quite simply, Split Flow is a more efficient pump selection for dual service applications. It saves energy, and thus reduces carbon emissions. Split Flow™ API centrifugal pumps provide a solution to oil refiners. |

NewsA ‘Practical Alternative’See new article on Split Flow™ in Pumps & Systems. Taking Occam’s Razor to refiningSee article on Split Flow™ in Hydrocarbon World. Welcome to SplitFlow Pumps.com. “The obvious often escapes us.” |

One Split Flow pump can do the work of two standard pumps, at significant energy and cost savings. The

One Split Flow pump can do the work of two standard pumps, at significant energy and cost savings. The