"Multiplicity ought not to be posited without necessity." — Occam's Razor Otherwise stated: |

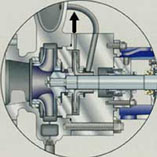

API Standard 610 and Overhung PumpsIt is common knowledge that two-stage overhung pumps have a tarnished reputation for reliability. This was the basis for the API Standard 610, Sixth and Seventh Editions, proscribing their use since January, 1981. Some two-stage overhung designs were subsequently modified to incorporate outboard bearings to enhance reliability as trade-off against increased initial cost.The API Standard 610, Eighth Edition, allows for the use of purchaser-specified, two-stage overhung designs, providing rotor stiffness criteria are addressed. (See more on API pecifications.)  (Figure 1) Horizontal single-stage overhung centrifugal process pump, featuring centerline mounted, back pull-out radial split case (Click on image to enlarge.) (Figure 1) Horizontal single-stage overhung centrifugal process pump, featuring centerline mounted, back pull-out radial split case (Click on image to enlarge.)Figure 1 illustrates an API Standard single-stage overhung pump and the same pump incorporating an auxiliary (booster) impeller. Figure 2 illustrates a conventional two-stage overhung design. It is obvious that the two-impeller (Split Flow) design is not a two-stage overhung type, where each of the two stages, in series, pump 100 percent of the design flow. The API 610 Taskforce has noted that the two-impeller design for dual service "...has a niche where it is desirable and does not want to discourage its application by inclusion in Table 1-1." (reference Eighth Edition). Pumps modified to incorporate the Split Flow feature satisfy the rotor stiffness criteria for two-stage overhung types, in accordance with API specifications. |

Split Flow™

|