"Multiplicity ought not to be posited without necessity." — Occam's Razor Otherwise stated: |

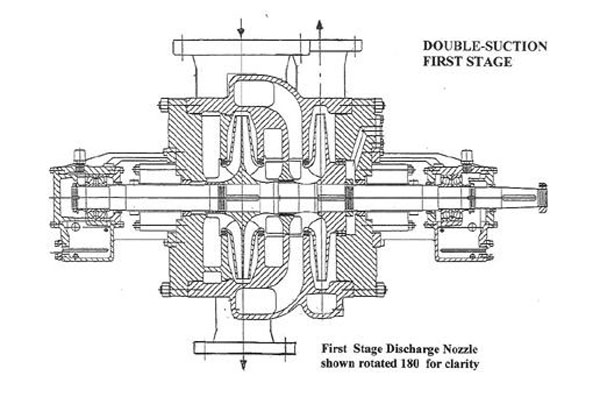

‘Big’ Split Flow™A two-stage, API between-bearings centrifugal process pump with radially split centerline-mounted case designed for high-temperature (up to 800°F) hydrocarbon service, separates a single inlet flowstream into two outlet flowstreams, one at first-stage discharge pressure and the other at second-stage discharge pressure. This Split Flow feature precludes the need for two separate pumps and saves energy when one pump is used for two separate process flowstreams. The pump is effectively two pumps in one, with impellers selected for the discrete process requirements of the individual flowstreams. Model H2R (API Type BB2) with Split Flow feature, double suction:

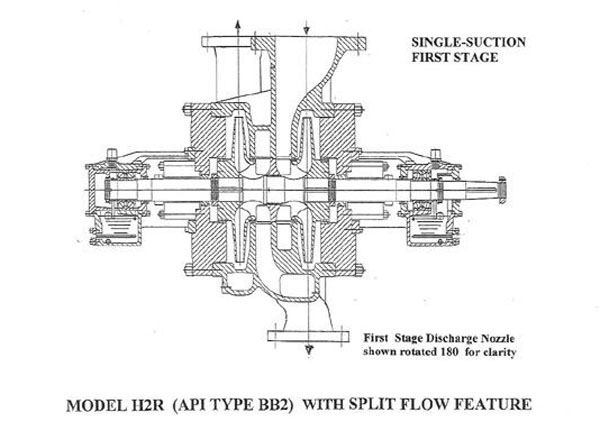

Model H2R (API Type BB2) with Split Flow feature, single suction:

Horizontal split case designs may be used for service temperatures below 400 degrees. and specific gravities above 0.70. An intermediate stage takeoff from the first impeller group is used when an opposed impeller design is selected. |

‘Big’ Split FlowHorizontal split case designs may be used for service temperatures below 400 degF. and specific gravities above 0.70. An intermediate stage takeoff from the first impeller group is used when an opposed impeller design is selected.

|